26 Feb What is an HDPE Liner?What is the Life Expectancy of these Liners?

HDPE (High-Density Polyethylene) liner is a type of geomembrane made from high-density polyethylene resin. HDPE liners are used in various containment applications, including landfill liners, pond liners, canal liners, reservoir liners, and secondary containment systems. They serve as impermeable barriers that prevent the migration of liquids or gases, providing environmental protection and containment of hazardous substances.

The life expectancy of HDPE liners Install can vary depending on factors such as installation quality, environmental conditions, chemical exposure, and maintenance practices. However, properly installed and maintained HDPE liners can have a lifespan ranging from 20 to 30 years or more in typical applications.

Several factors contribute to the longevity of HDPE liners:

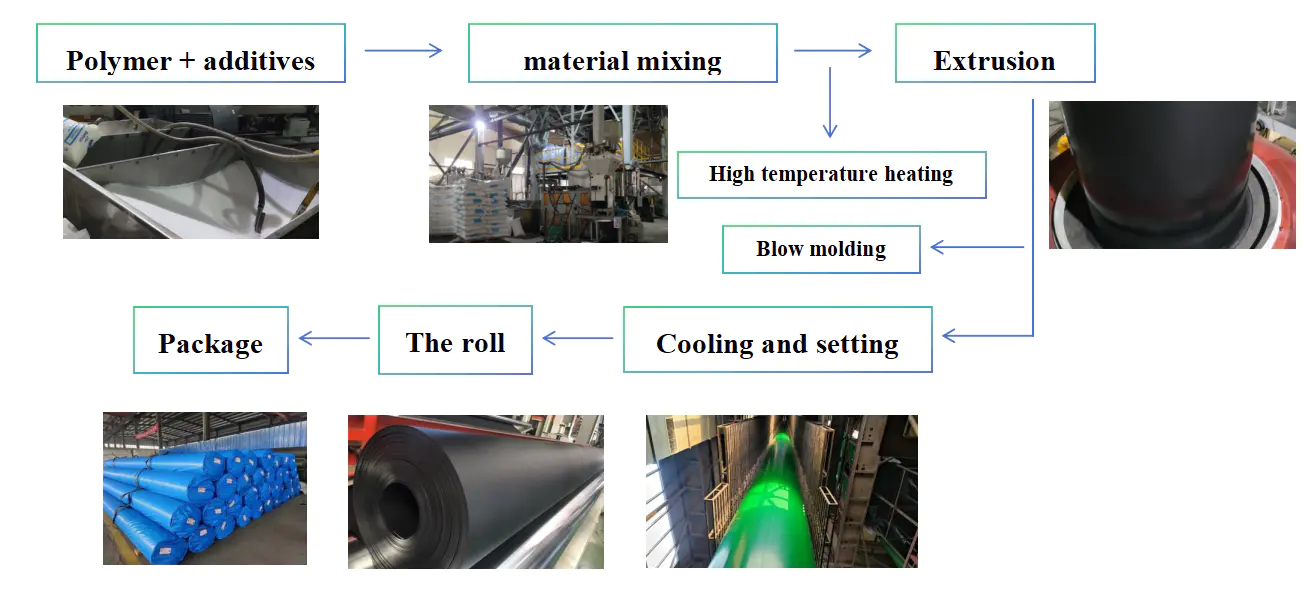

1.Material Quality: High-quality HDPE resin and manufacturing processes ensure the durability and performance of the liner material.

2.Thickness: Thicker HDPE liners offer increased puncture resistance and durability, extending their lifespan in harsh environments.

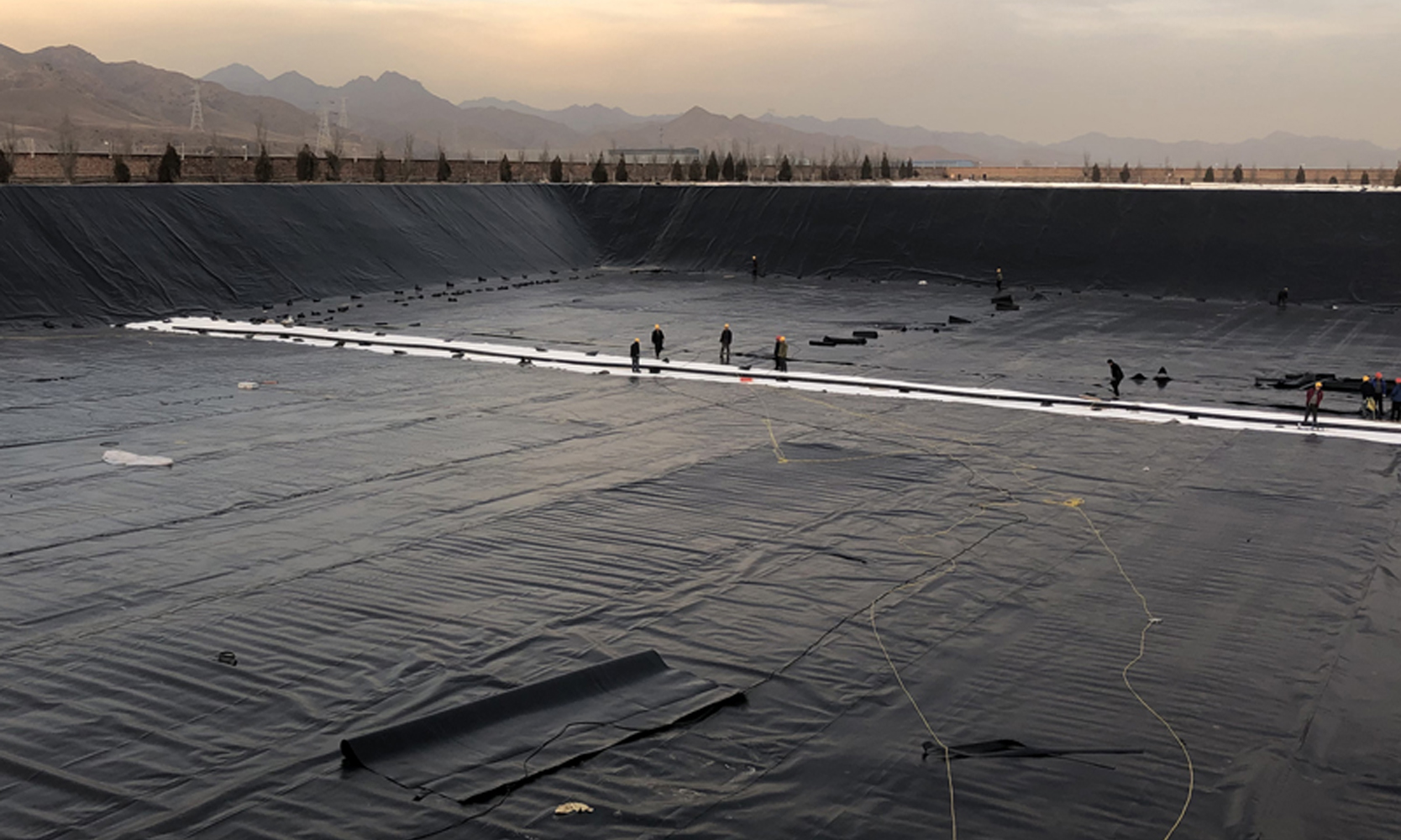

3.Installation: Proper installation techniques, including surface preparation, seam welding, and anchoring, are critical for ensuring the integrity and longevity of HDPE liners.

4.Environmental Conditions: Exposure to UV radiation, temperature fluctuations, and chemical exposure can affect the degradation rate of HDPE liners. Implementing measures such as UV stabilization additives and protective coverings can mitigate these effects and prolong the lifespan of the liner.

5.Maintenance: Regular inspection, cleaning, and repair of HDPE liners can help identify and address issues early, preventing potential damage and extending the liner’s lifespan.

Composition and Construction

HDPE liners are made from high-density polyethylene resin, a thermoplastic polymer known for its excellent chemical resistance, durability, and flexibility. The manufacturing process involves extruding or calendering the HDPE resin into thin sheets, which are then further processed to form geomembrane liners.

HDPE liners are typically available in rolls or panels of various widths and thicknesses, ranging from 0.5 to 3 millimeters or more. They may feature smooth or textured surfaces, depending on the application requirements. Textured surfaces provide enhanced frictional resistance and interface shear strength, making them suitable for steep slopes and high-stress applications.

HDPE Liner Properties and Performance

HDPE liners exhibit several properties that make them well-suited for containment applications:

1.Impermeability: HDPE liners are highly impermeable to liquids, gases, and vapors, providing effective containment and environmental protection against leakage or migration of hazardous substances.

2.Chemical Resistance: HDPE liners offer excellent resistance to a wide range of chemicals, including acids, bases, solvents, and hydrocarbons, making them suitable for applications with aggressive chemical environments.

3.Flexibility: Despite their high tensile strength and puncture resistance, HDPE liners remain flexible and conformable to irregular surfaces and contours, allowing for easy installation over challenging terrain.

4.UV Resistance: HDPE liners are resistant to degradation from ultraviolet (UV) radiation, although prolonged exposure to sunlight may cause some degradation over time. UV stabilization additives can be incorporated into the liner material to enhance resistance to UV degradation.

5.Temperature Stability: HDPE liners maintain their mechanical properties and performance over a wide temperature range, from sub-zero temperatures to elevated temperatures, making them suitable for use in various climates and environmental conditions.

Applications

HDPE liners find applications in a wide range of containment projects, including:

1.Landfills: HDPE liners serve as bottom liners, cover liners, and leachate collection systems in municipal solid waste landfills, hazardous waste landfills, and industrial landfills.

2.Ponds and Reservoirs: HDPE liners are used to line ponds, reservoirs, lagoons, and water storage tanks to prevent seepage, control water loss, and protect against contamination.

3.Canals and Irrigation Systems: HDPE liners provide lining solutions for irrigation canals, channels, ditches, and water conveyance systems, improving water efficiency and reducing seepage losses.

4.Secondary Containment: HDPE liners are utilized in secondary containment systems for storage tanks, chemical storage areas, and industrial facilities to prevent leaks and spills from contaminating the surrounding environment.

5.Mining and Environmental Remediation: HDPE liners are employed in mining operations, tailings ponds, and environmental remediation projects to contain and control contaminants, tailings, and wastewater.

Overall, HDPE liners offer a versatile, durable, and cost-effective solution for containment applications, providing reliable environmental protection and containment of hazardous substances. With proper design, installation, and maintenance, HDPE liners can provide long-term performance and peace of mind for a wide range of projects.

Sam4092

Posted at 20:24h, 30 AprilVery good https://is.gd/N1ikS2