03 Jan What is Geotextile?

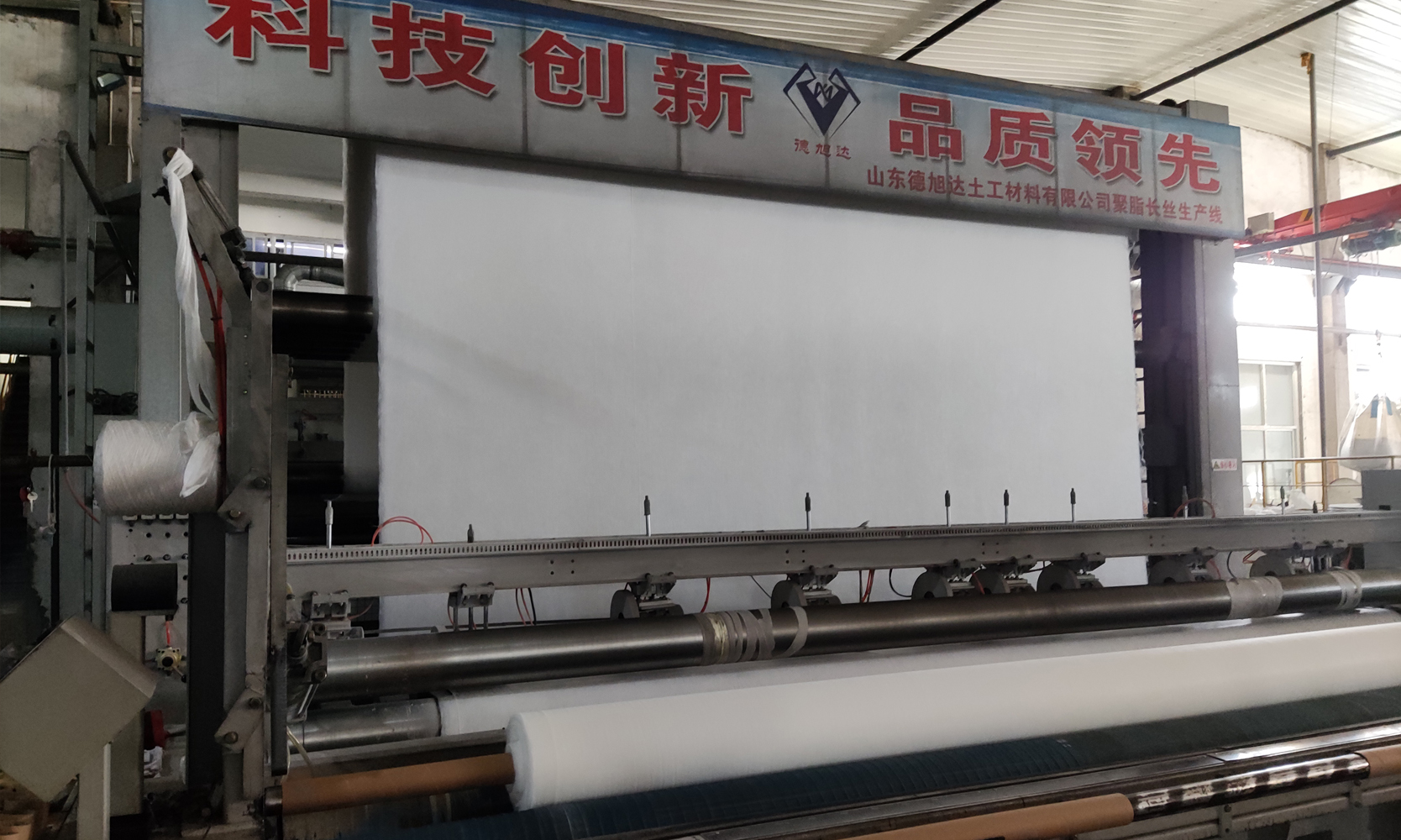

Geotextile Introduction

Geotextile, also known as geofabric, is a water-permeable geosynthetic material made of synthetic fibers by needling or weaving. Geotextile is one of the geosynthetic materials, the finished product is cloth-like, the general width is 4-6 meters, the length is 50-100 meters. Geotextiles are divided into woven geotextiles and non-woven geotextiles.

Geotextile Features

1, High strength: Due to the use of plastic fibers, it can maintain sufficient strength and elongation in both wet and dry conditions

2, Corrosion resistance: It can resist corrosion for a long time in soil and water with different pH

3, Good water permeability: There is a gap between the fibers, so it has good water seepage performance.

4, Good microbial resistance: Not damaged by microorganisms and insects

5, The construction is convenient: Because the material is gentle, it is convenient to transport, lay and construction.

6, Complete specifications: Width up to 9 meters. It is the widest product in China. And the mass per unit area is 100-1000g/m2

Geotextile Function

1:Isolation

Construction materials (such as soil and sand, soil and concrete, etc.) with different physical properties (particle size, distribution, consistency and density, etc.) are isolated by using polyester staple fiber needled geotextiles. So that two or more materials do not lose, do not mix, maintain the overall structure and function of the material, so that the carrying capacity of the structure is strengthened.

2:Filtration (Inverse filtration)

When the water flows into the coarse soil layer from the fine soil layer, the use of polyester staple fiber needle geotextile good permeability and water permeability, so that the water through, and effectively intercept the soil particles, fine sand, small stone, etc., in order to maintain the stability of soil and water engineering.

3:Water drainage

Polyester staple fiber needled geotextile has good water conductivity. It can form a drainage channel inside the soil, and exhaust the excess liquid and gas in the soil structure.

4:Reinforcement

Use polyester staple fiber needled geotextile to enhance the tensile strength and deformation resistance of soil, enhance the stability of building structure, and improve the quality of soil

5:Protection

When the water scour the soil, the concentrated stress can be effectively diffused, transmitted or decomposed to prevent the soil from being damaged by external forces, which protects the soil.

6:Anti-puncture

Combined with geomembrane to become a composite waterproof and impermeable material, play a role in preventing puncture.

High tensile strength, good permeability and air permeability, high temperature resistance, freezing resistance, aging resistance, corrosion resistance, moth proof.

Polyester staple fiber needled geotextile is a widely used geosynthetic material. It is widely used in railway roadbed reinforcement, highway pavement maintenance, sports hall, dam protection, hydraulic construction isolation, tunnel, coastal beaches, reclamation, environmental protection and other projects. It has light weight, low cost, corrosion resistance, with reverse filtration, drainage, isolation, enhancement and other excellent performance.

Geotextile Usage

Widely used in water conservancy, power, mine, road and railway and other geoengineering:

1. Filter material for soil layer separation;

2, Drainage materials for reservoirs, mining and mineral processing, drainage materials for high-rise building foundations;

3. Anti-erosion materials for river dykes and slope protection;

4, Railway, road, airport runway roadbed reinforcement materials, swamp area road reinforcement materials;

5, Anti-frost, anti-freeze insulation materials;

6, Asphalt pavement anti-crack material.

Geotextile Application Area

(1) For reinforcement in the backfill of the retaining wall, or for anchoring the panel of the retaining wall. Construction of wraparound retaining walls or abutments.

(2) Strengthen the flexible pavement, repair the cracks on the road, and prevent the pavement from reflecting cracks.

(3) Increase the stability of gravel slope and reinforced soil to prevent soil erosion and freezing damage at low temperatures.

(4) The isolation layer between the road ballast and the roadbed, or the isolation layer between the roadbed and the soft foundation.

(5) Isolation layer between artificial earth filling, rockfill or material field and foundation, and isolation between different frozen soil layers. Backfiltration and reinforcement.

(6) The filter layer of the initial upstream dam surface of the ash dam or tailings dam, and the filter layer of the drainage system in the backfill soil of the retaining wall.

(7) The filter layer around the drainage dark pipe or the gravel drainage dark ditch.

(8) The filter layer of water Wells, relief Wells or baroclinic pipes in water conservancy projects.

(9) Isolation layer of geotextiles between roads, airports, railway tracks and artificial rockfills and the foundation.

(10) The earth dam internal vertical or horizontal drainage, buried in the soil to dissipate the void water pressure.

(11) Drainage behind impermeable geomembrane or under concrete protection in earth DAMS or earth embankments.

(12) Eliminate water seepage around the tunnel, reduce the external water pressure borne by the lining and water seepage around the buildings.

(13) Drainage of the foundation of the artificially filled ground sports ground.

(14) Roads (including temporary roads) are used to strengthen weak foundations in projects such as railways, embankments, earth-rock DAMS, airports and sports grounds.

Establish business contacts for geotextile projects

If you are looking for a geotextile manufacturer for your project, don’t hesitate to contact us.

No Comments