14 Jan How to ensure the high quality of geosynthetic materials?

Foreword

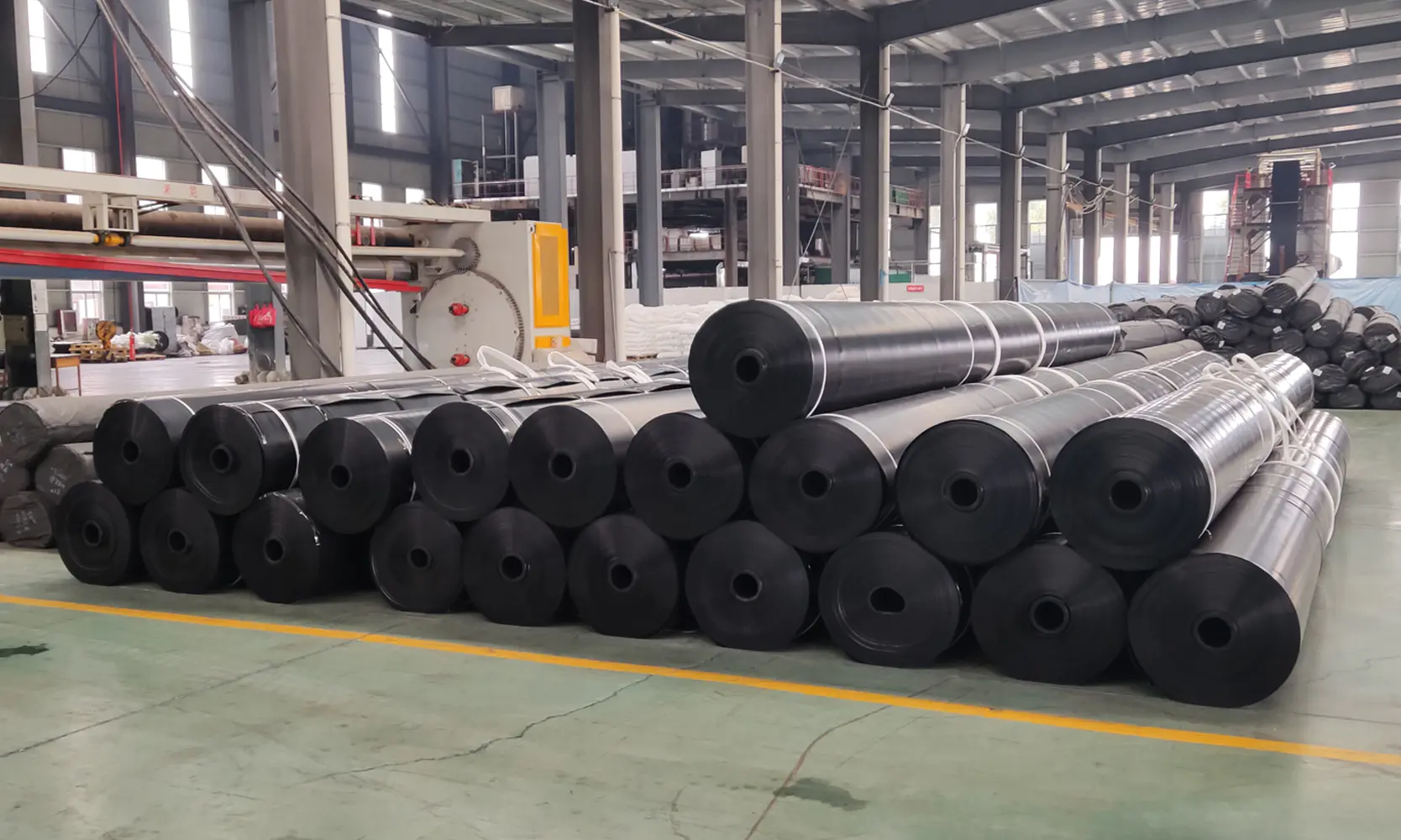

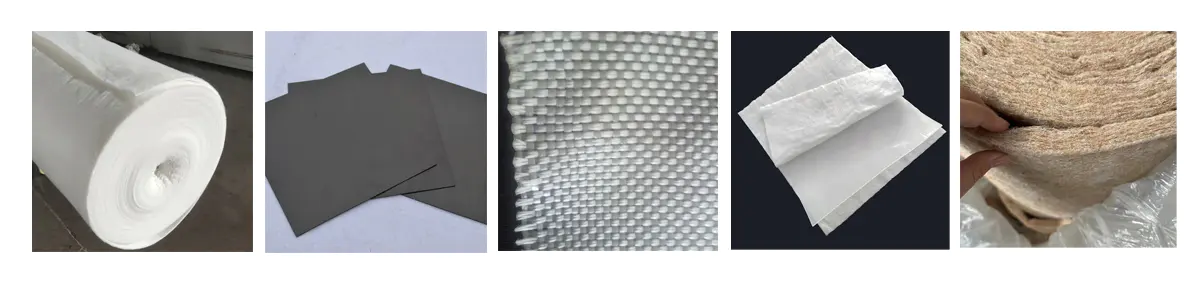

Geosynthetic materials are artificial synthetic materials used in the fields of civil engineering and geotechnical engineering. Geosynthetic material series products (such as geotextiles, geomembranes, geogrids, geocells, etc.) have many advantages, such as high strength , corrosion resistance, anti-aging, convenient construction, etc. As the use of geosynthetic materials in the world increases year by year, there are also higher requirements for the quality of geosynthetic materials.

As a geosynthetic material manufacturer from China, we have always believe that only by putting quality first can we better serve our customers and propose friendly and long-term cooperative relationships.

We have always maintained our passion for geosynthetics, which has driven us to produce high-quality products. This article will detail our customer service and quality control measures.

Selection of geosynthetic raw materials

1.1 Performance of raw materials: According to specific engineering applications, materials with corresponding properties are selected. For example, for projects with high waterproofing or anti-seepage requirements, we will choose products with high waterproofness and low permeability. For reinforcement projects, we will choose materials with high strength and good tensile properties.

Before producing a specific product, we usually test the raw materials to ensure that the raw materials meet the requirements for product production, because the performance of the raw materials will ultimately determine the performance of the product.

1.2 Durability: Before starting the project, you need to consider the durability of the product, including aging resistance, chemical corrosion resistance, biological corrosion resistance, etc. Different raw materials are suitable for different environments. Choosing appropriate high-quality products can ensure stable performance during long-term use process.

1.3 Environmental adaptability: Before starting the project, it is also necessary to consider the environmental conditions of the area where the project is located. For example, in an environment with high pH, polypropylene materials should be considered. The acid and alkali resistance of polypropylene is higher than that of polyester and other materials.

1.4 Standards of products: Different products correspond to different performance indicators. For example, the implementation standard of HDPE geomembrane is ASTM-GM13, while the implementation standard of LLDPE geomembrane is ASTM-GM17.

Control of production process

2.1 Equipment maintenance: As a manufacturer of geosynthetic materials, we believe that regular maintenance of equipment is needed to ensure that it can maintain optimal performance at any times. In addition, the equipment needs to be inspected before production and after all the problems are eliminated, production can be carried out. When the order is completed, the equipment needs to be cleaned before the next order is started, especially the raw materials retained in the equipment to ensure that the raw materials used in the next order are the latest ratio.

2.2 Production process control: During the product production process, it is necessary to monitor all aspects of the production process, including feeding, mixing, extrusion, molding and other processes to ensure the stability of process parameters, which allows us to produce more stable high-quality products.

2.3 Employee training: Usually we will train employees regularly, which may be a week or a month. Although our employees are experienced workers, timely training can strengthen their operating skills and quality awareness, and understand the importance of each process.

2.4 Control of the production environment: Keep the production environment clean and tidy, and control the temperature, humidity and other factors in the workshop. Avoid the impact of dust and debris on product quality.

2.5 Records and Traceability: We have complete production records, including batches of raw materials, production dates, process parameters and other information, which helps track product quality problems and identify the causes for improvement and adjustment.

Quality testing and certification

3.1 Product performance testing: We are equipped with laboratories and technical personnel. We require each batch of products to be tested. These tests include product physical properties, chemical performance analysis, hydraulic performance testing, durability testing, etc. This is the last inspection before we confirm that the product is qualified. We require that the goods leaving the factory must be qualified products.

3.2 Comply with index requirements: We will produce according to the product performance indicators agreed with the customer. This is very important. Only products that meet the requirements can be used better.

3.3 Third-party testing: We agree and support third-party testing, which can be sending samples or taking samples. We believe this is an important process for customers to ensure product qualifications.

Technological innovation and research and development

4.1 Improvement of production process: We have always maintained good contact with equipment manufacturers. We will put forward our requirements to update the equipment according to the actual situation. This will also help improve our production efficiency and product stability. Excellent production technology can provide basic support for our research and development of new products.

4.2 Innovation of new products: We are always ready to explore and develop new geosynthetic materials, which is an effective way for us to remain competitive.

4.3 Sustainable development: We are always paying attention to the research and development and innovation of new raw materials, such as degradable and recyclable synthetic materials, to reduce the impact on the environment.

4.4 Expansion of application fields: Explore new application fields of geosynthetic materials, such as marine engineering, geological disaster protection, ecological environment restoration, etc.

Our services

5.1 Product customization: As a manufacturer of geosynthetic materials, we are very willing to customize products for customers, including customized services in terms of size, specifications, performance indicators, etc. according to the customer’s specific requirements.

5.2 Technical consulting: Provide customers with technical consulting services for geosynthetic materials, including raw material selection, design suggestions, construction plans, etc.

5.3 Project services: Closely contact the customer’s project team, pay attention to the construction progress, and ensure that our materials can be delivered on time.

5.4 Quality Assurance: We put quality control first, and perfect quality control processes and personnel can make it easier for us to control quality.

5.5 Solution: We have more than ten years of manufacturing and installation experience, and can provide better geosynthetic material solutions based on our rich experience.

Continuous Improvement

In order to maintain our competitiveness in the geosynthetics industry for a long time and meet the changing market demand, we will actively collect and analyze customer feedback, and maintain close partnerships with suppliers, customers, and research institutions. We are very Willing to jointly carry out technology research and development and innovation projects.

In addition, we have established a continuous evaluation mechanism. From the beginning of raw material procurement to the completion of customer construction, we will evaluate each order to make up for our shortcomings and improve our services at any time.

No Comments