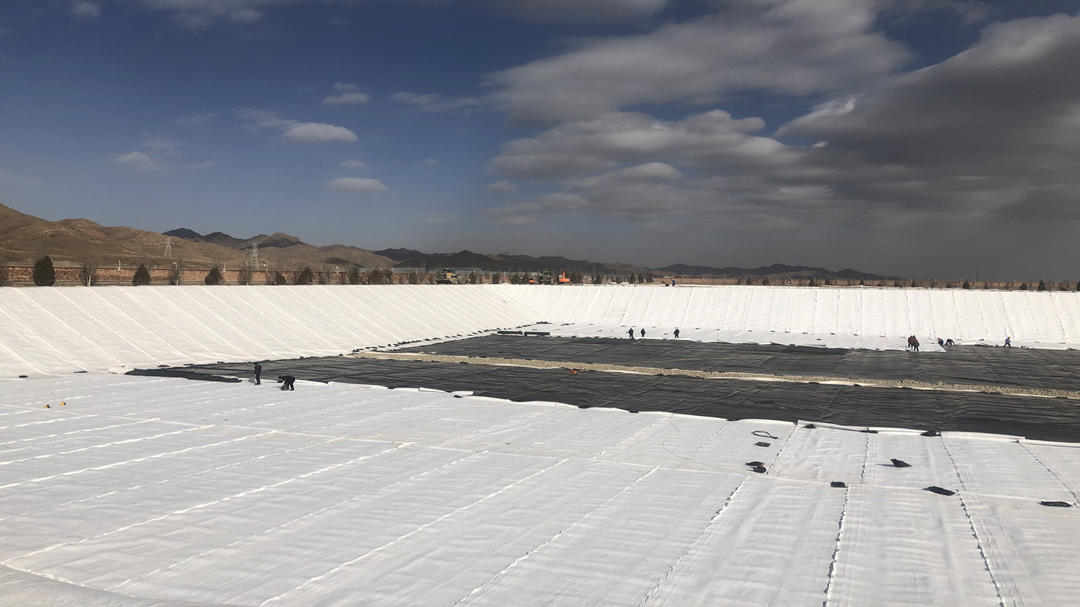

06 Jan how to geotextile laying fabric better

Things to consider before geotextile laying

There are many things that need to be considered before geotextile laying. Geotextile rolls should be protected from damage before installation and unfold. They should be stacked in a place that is flat and does not accumulate water. The height of the pile should not exceed four rolls, and the identification tag of the roll can be seen. Geotextile rolls must be covered with an opaque material to prevent UV aging. In the storage process, maintain the integrity of the label and the integrity of the data. Geotextile rolls must be protected from damage during transportation (including on-site transportation from the material storage site to the work site).

Geotextile rolls that are physically damaged must be repaired. The geotextile with severe wear cannot be used. Any geotextile that comes into contact with the leaked chemical agent is not allowed to be used in this project.

The basic requirements of geotextile laying

- When laying geotextile,the joint must intersect with the slope line; Where there is balance with the foot of the slope or where there may be stress, the distance between the horizontal joints shall be greater than 1.5m.

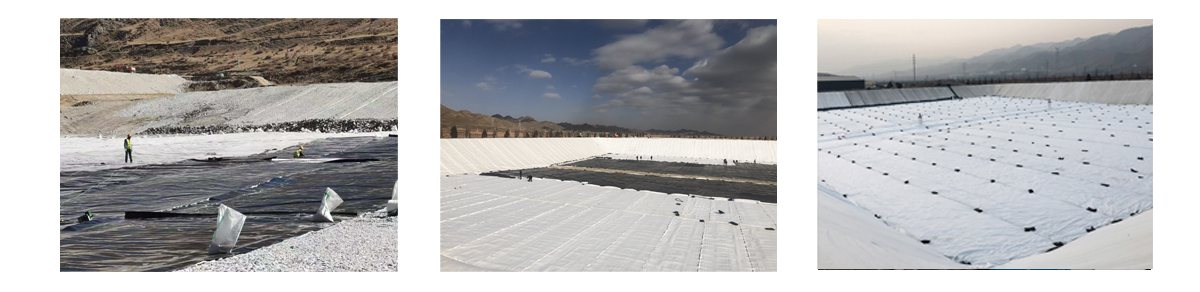

- On the slope, anchor one end of the geotextile, the rolls is then lowered along the slope to ensure that the geotextile remains tensioned.

- All geotextiles must be pressed with sand bags, sand bags will be used during the laying and retained until the laying of the above layer of material.

Geotextile Laying Method

1, When geotextile laying, it should be rolled manually. The geotextile surface should be smooth, and appropriate deformation margin.

2, The installation of filament or short filament geotextile is usually used by several methods of overlapping, stitching and welding. The width of stitching and welding is generally more than 0.1m, and the overlapping width is generally more than 0.2m. Geotextiles that may be exposed for a long time should be welded or stitched.

3.Stitching of geotextiles:

All stitching must be done continuously (for example, spot stitching is not allowed). The geotextile must overlap at least 150mm before overlapping. The minimum stitch distance from the woven edge (the exposed edge of the material) is at least 25mm.

The stitched geotextile joint shall include a line of chain stitch with a lock. The thread used for stitching should be a resin material with a minimum tension of more than 60N, and have chemical corrosion resistance and UV resistance equal to or exceeding that of geotextiles.

Any “missing stitches” in the stitched geotextile must be re-stitched at the affected area.

Appropriate measures must be taken to prevent soil, particulate matter or foreign substances from entering the geotextile layer after installation.

The lapping of geotextile can be divided into natural overlapping, stitching or welding according to the terrain and the function of use.

4.In the construction, the geotextiles below the geomembrane are naturally overlapped, and the geotextiles above the geomembrane are stitched or welded with hot air welding. Hot air welding is the preferred connection method of filament geotextile. That is, the connection of two pieces of geotextile is heated at high temperature at a hot air gun, so that part of it reaches a melting state, and immediately uses a certain external force to make it firmly bonded together. In the case of wet (rain and snow) weather can not be thermal adhesive connection, geotextile should take another method, suture connection method, that is, use a special sewing machine for two-line suture connection, and use the chemical UV resistant suture line.

The minimum width is 10cm when stitching, 20cm when natural overlapping and 20cm when hot air welding.

5, For sewing,use the suture line that is same quality as geotextile. The suture line should be made of materials that are more resistant to chemical damage and ultraviolet light.

6. Geomembrane is laid after the geotextile is laid and approved by the on-site supervision engineer.

7. The geotextile on the geomembrane is laid as above after the geomembrane is approved by Party A and the supervisor.

8, The corresponding geotextile codes of each layer are TN and BN.

9.The two layers of geotextile above and below the membrane should be buried in the anchoring groove together with the geomembrane.

No Comments