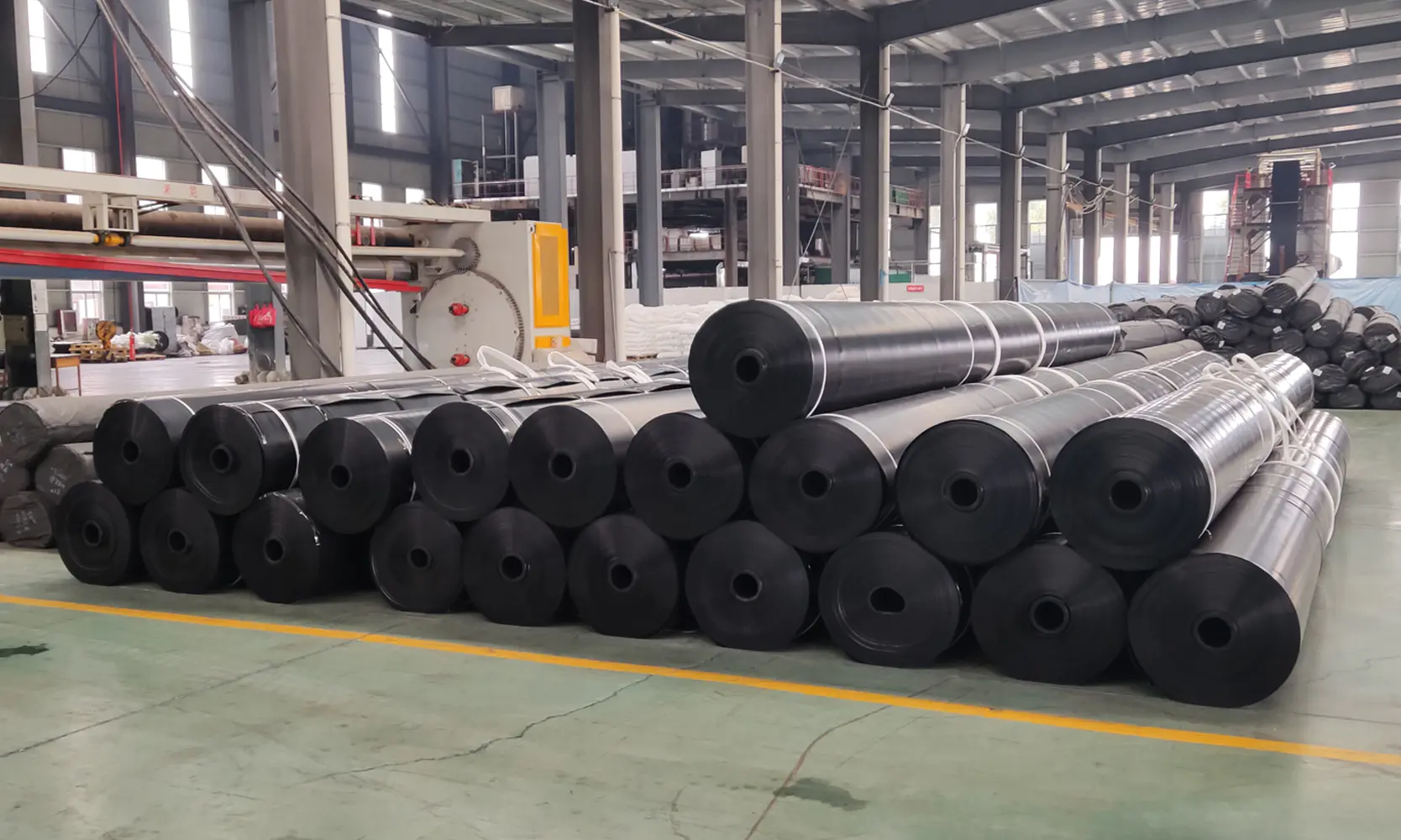

19 Feb Issues you should consider before ordering HDPE liner?

Site Conditions and Environmental Factors

Assess the site conditions where the HDPE liner will be installed, including soil type, slope, groundwater levels, and exposure to UV radiation. Consider environmental factors such as temperature fluctuations, chemical exposure, and potential for mechanical damage. Understanding these factors will help determine the appropriate thickness, material specifications, and installation methods for the HDPE liner.

Project Requirements and Specifications

Clearly define the project requirements, including the desired dimensions, thickness, and material properties of the HDPE liner. Consider any specific regulatory or performance standards that must be met, such as ASTM standards for geomembranes or industry-specific requirements for containment systems. Ensure that the HDPE liner selected meets or exceeds these specifications.

HDPE Liner Compatibility with Other Materials

Evaluate the compatibility of the HDPE liner with other materials and components used in the project, such as geotextiles, drainage systems, concrete structures, and chemical additives. Ensure that the HDPE liner is compatible with any adhesives, sealants, or welding techniques that will be used for installation to prevent compatibility issues and ensure long-term performance.

Installation Method and Techniques

Determine the most suitable installation method and techniques for the HDPE liner based on site conditions, project requirements, and available resources. Consider factors such as liner deployment, seaming methods (e.g., heat fusion, extrusion welding), anchoring or ballasting techniques, and quality control measures. Ensure that installation personnel are trained and qualified to properly install the HDPE liner according to industry best practices.

Quality Assurance and Testing

Establish quality assurance protocols and testing procedures to ensure the HDPE liner meets quality standards and performance requirements. Conduct pre-installation inspections and testing of the liner material to verify dimensions, thickness, and material properties. Perform quality control checks during installation, including seam testing, leak detection, and destructive testing if necessary, to ensure the integrity and reliability of the liner system.

Long-Term Performance and Maintenance

Consider the long-term performance and maintenance requirements of the HDPE liner, including durability, resistance to environmental factors, and anticipated service life. Develop a maintenance plan that includes routine inspections, monitoring of performance indicators (e.g., leakage rates, deformation), and proactive measures to address any issues or deterioration over time. Ensure that maintenance personnel are trained and equipped to properly maintain the HDPE liner to maximize its lifespan and effectiveness.

Local regulations and environmental protection requirements

Welding is required when installing HDPE liner. In some special areas, this may conflict with environmental protection requirements. If HDPE liner cannot be installed on site due to policy requirements, prefabricated geomembrane liner can be considered.

Specifications and sizes

Choosing appropriate specifications and sizes is a very important issue. (When considering the width, please don’t forget to reserve the welding seam of the geomembrane.) In addition, if you consider overseas imports, customs procedures and sea freight are also required.

Factors to consider

By carefully considering these issues before ordering HDPE liner, you can ensure that the liner selected is suitable for your project needs, meets quality standards, and provides reliable performance over its intended lifespan. Consulting with experienced professionals, such as geotechnical engineers, geomembrane installers, or material suppliers, can also provide valuable guidance and expertise in selecting and installing the appropriate HDPE liner for your project.

No Comments