04 Jan Non Woven Geotextile VS Woven Geotextile

Geotextile Description

Geotextile refers to the fabric used in geotechnical engineering.Geotextiles can be divided into woven geotextiles and non woven geotextiles. According to the different raw materials, it can be divided into polyester, polypropylene, or plant fiber (such as coconut silk, etc.); In order to ensure the smooth progress of your project, it means that you need to understand the difference between different varieties of geotextile.

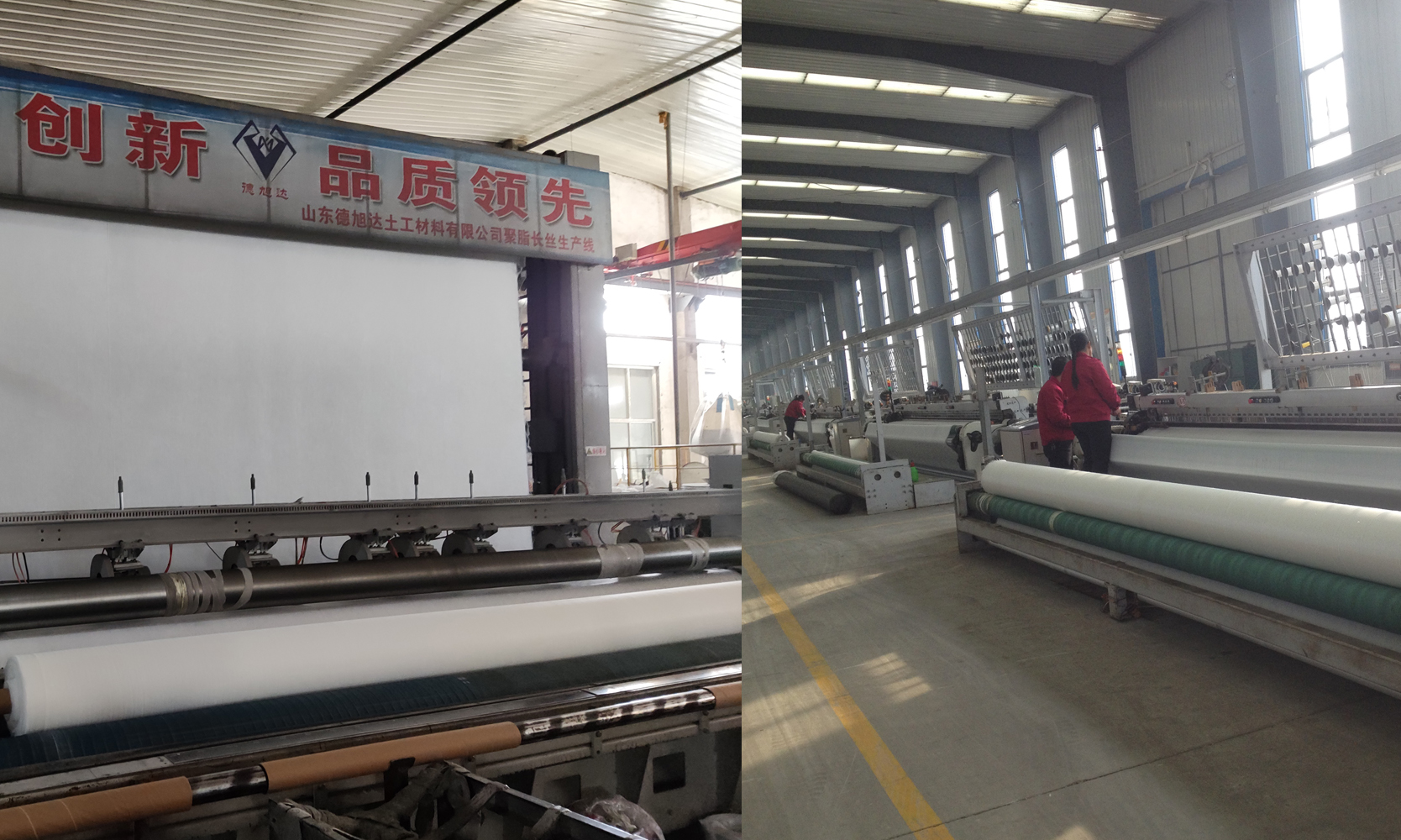

Non woven geotextile manufacturing process:

Non-woven geotextiles: non-woven geotextiles are usually made of polyester or polypropylene fiber as raw materials, manufactured by needling process. The fiber arrangement order is similar to the three-dimensional structure. The fibers are intertwined with each other, and have good mechanical properties in all directions, while also having a large aperture, which makes non-woven geotextiles usually have good filtration performance.

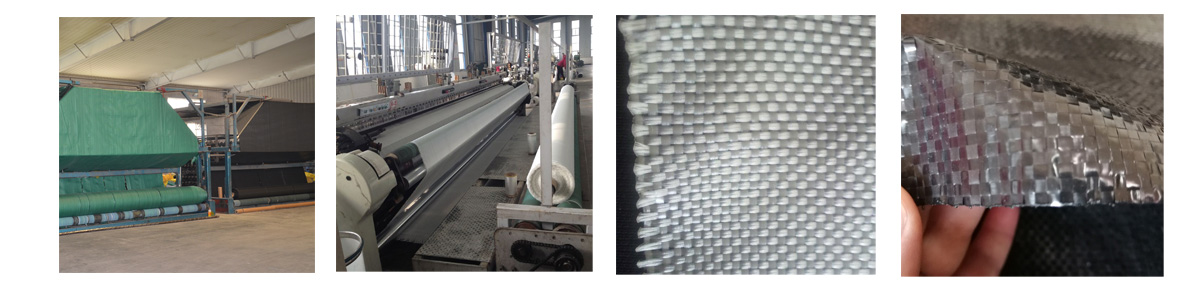

Woven geotextile manufacturing process

Woven geotextile are manufactured through the weaving process, and polyester, polypropylene or polyethylene materials can be selected according to different use scenarios. The process is more complex than non-woven geotextiles, but its strength is often higher than non-woven geotextiles.

Performance index

The corresponding indicators of different varieties of geotextile are different, and different varieties of geotextile products need to be selected according to the design requirements of the project.

Woven geotextiles usually have better water permeability, we need to understand its water permeability parameters. We refer to the vertical permeability coefficient of POLYESTER FILAMENT NONWOVEN GEOTEXTILE: Kx(10-1~10-3), K=1.0~9.9. The vertical permeability coefficient of SYNTHETIC FILAMENT WOVEN GEOTEXTTILE is: Kx(10-5~10-2), K=1.0 to 9.9. It can be seen that woven geotextiles have better water permeability than non-woven geotextiles.

Also take the above products as a comparison, in terms of tensile strength, the POLYESTER FILAMENT NONWOVEN GEOTEXTILE has a tensile strength of 6KN~54KN(KN/M) while the SYNTHETIC FILAMENT WOVEN GEOTEXTTILE has a tensile strength of 35KN~250KN (KN/M). It can be seen that woven geotextiles are superior to non-woven geotextiles in terms of mechanical properties.

Of course, this is not to say whether the product is good or bad, we are only talking about which geotextile is more suitable for your project.

Output And Price

Because the process of non-woven geotextiles is simple compared with woven geotextiles, the daily output is much higher than the output of woven geotextiles. According to the thickness of non-woven geotextiles, the general output is 10,000 square meters/day – 30,000 square meters/day, and the price is relatively low. Because the process of woven geotextiles is complex and the output is low, so the price is generally higher than that of non-woven geotextiles.

Contact Us

All indicators are very important when you need to choose geotextiles for a project. Choosing the right geotextile helps extend its service life and improve the overall design. Please feel free to contact us if you are considering choosing a geotextile.

No Comments