22 May The Role of Geosynthetics in Landfill Lining Systems

Key Functions of Geosynthetics in landfill Lining Systems

- Containment:

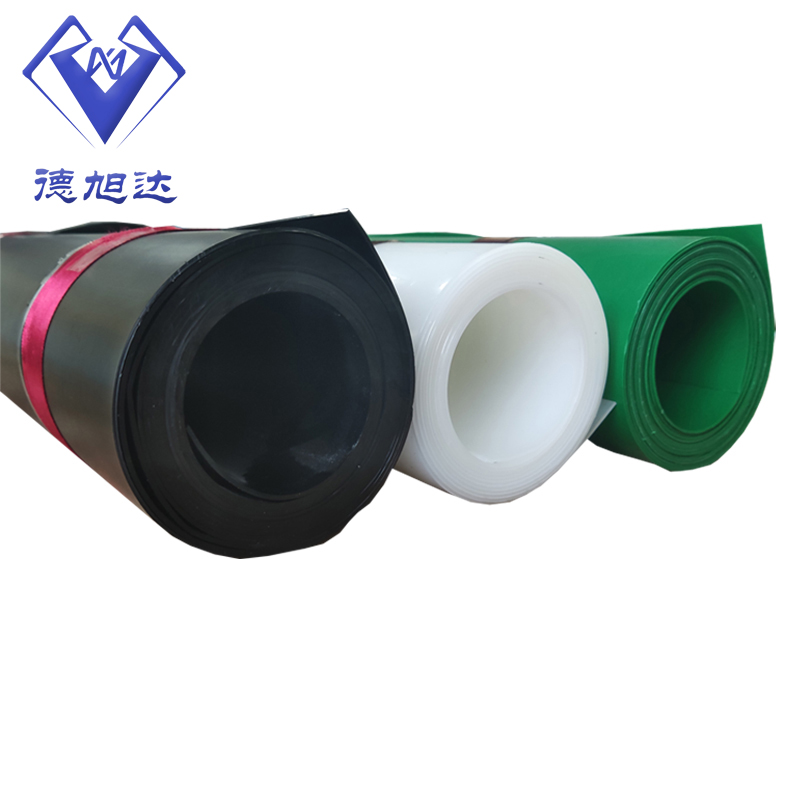

- Geomembranes: Act as primary barriers to prevent the migration of leachate and gases into the environment. Made from materials like high-density polyethylene (HDPE), they provide excellent chemical resistance and impermeability.

- Geosynthetic Clay Liners (GCLs): Consist of bentonite clay sandwiched between geotextiles or bonded to geomembranes. They combine the low permeability of natural clay with the durability of synthetic materials, providing a secondary containment layer.

- Geomembranes: Act as primary barriers to prevent the migration of leachate and gases into the environment. Made from materials like high-density polyethylene (HDPE), they provide excellent chemical resistance and impermeability.

- Separation:

- Filtration:

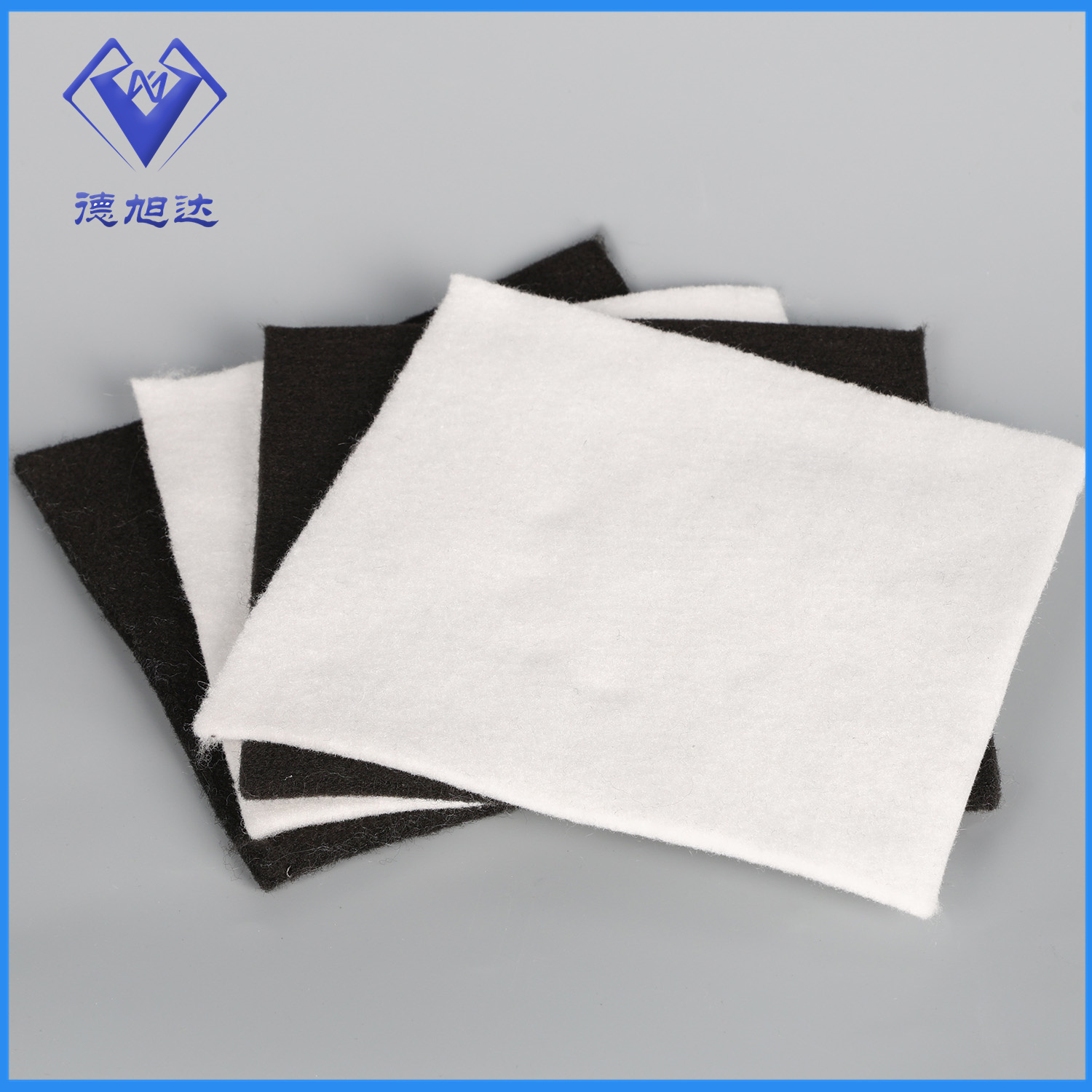

- Geotextiles: Allow water to pass through while retaining soil particles. This filtration capability is essential in preventing clogging in drainage layers and maintaining the efficiency of leachate collection systems.

- Drainage:

- Geonets and Geocomposites: Facilitate the efficient drainage of leachate and gases. Geonets provide high flow capacity, while geocomposites, which combine geonets with geotextiles, enhance drainage and protect underlying geomembranes from punctures.

- Reinforcement and Stabilization:

- Geogrids: Provide structural reinforcement to landfill slopes and covers. They improve stability by distributing loads and reducing deformation, which is crucial for maintaining the integrity of the landfill structure.

- Protection:

- Geotextiles: Protect geomembranes from punctures and mechanical damage during installation and operation. They act as cushioning layers, distributing stresses and extending the lifespan of the liner system.

Specific Applications of Geosynthetics in Landfill Lining Systems

- Base Liner Systems:

- Geomembranes and GCLs are used to create impermeable base liners that prevent leachate from escaping into the ground.

- Geotextiles and geocomposites are included to enhance drainage and protect the integrity of the liner.

- Leachate Collection Systems:

- Geonets and geocomposites are placed above the base liner to facilitate the collection and removal of leachate, preventing buildup and reducing hydraulic pressure on the liner.

- Cap and Cover Systems:

- Geomembranes and geotextiles are used in the final cover system to prevent water infiltration, minimize leachate generation, and reduce gas emissions.

- Geogrids reinforce the cover system, maintaining stability and preventing erosion.

- Gas Management Systems:

- Geonets and geocomposites assist in the collection and venting of landfill gases, preventing gas buildup and potential hazards.

- Geotextiles in combination with these systems ensure efficient gas flow and protection of underlying layers.

Landfill Lining Systems

Benefits of Using Geosynthetics in Landfills

- Enhanced Environmental Protection: Geosynthetics significantly reduce the risk of environmental contamination by providing robust barriers against leachate and gas migration.

- Improved Structural Stability: Reinforcement provided by geogrids and geotextiles enhances the stability of landfill structures, preventing failures and extending the lifespan of the landfill.

- Cost-Effectiveness: Geosynthetics can be more cost-effective than traditional materials, offering easier installation and longer service life, which reduces maintenance and operational costs.

- Versatility and Adaptability: The wide range of geosynthetic products allows for customized solutions tailored to specific landfill conditions and regulatory requirements.

- Efficiency in Installation: Geosynthetics are relatively easy and quick to install compared to traditional materials, speeding up construction timelines and reducing labor costs.

Conclusion

Geosynthetics are indispensable in modern landfill design and operation. They provide critical functions such as containment, filtration, drainage, reinforcement, and protection, ensuring the safe and efficient management of waste. By incorporating geosynthetics, landfills can achieve higher levels of environmental protection, structural integrity, and operational efficiency.

No Comments