13 Jan Factors Affecting the Service Life of HDPE Liner

Foreword

HDPE liner is made of high-density polyethylene and is a high-performance geomembrane product. Usually HDPE liner has a service life of 50 to 80 years, but this is not static. Its service life is affected by many factors, such as its quality, usage environment, installation, etc.

Raw materials of HDPE liner

1.1 Polymer raw materials: Geomembranes are usually made of polymer materials, such as (HDPE, LDPE or PVC). The quality and stability of the polymer play a key role in the durability of the geomembrane. High-quality polymers usually have better resistance to aging and chemical corrosion, which determines the service life of the geomembrane.

1.2 Additives: In order to improve the performance of the geomembrane, we often add a certain amount of additives, such as antioxidants, UV stabilizers, anti-aging agents, etc. These additives can enhance the anti-aging performance of the geomembrane, delay the degradation rate of the material, and improve Geomembrane usage time.

1.3 Purity of the polymer: The purity of the polymer and additives will affect the quality and performance of the geomembrane. Generally speaking, we will test the raw materials and only approve the use when the required data is met, because low-purity additives will exist. There are many impurities and pollutants, which will cause the performance of the geomembrane to be unstable and prone to aging, cracking or leakage problems.

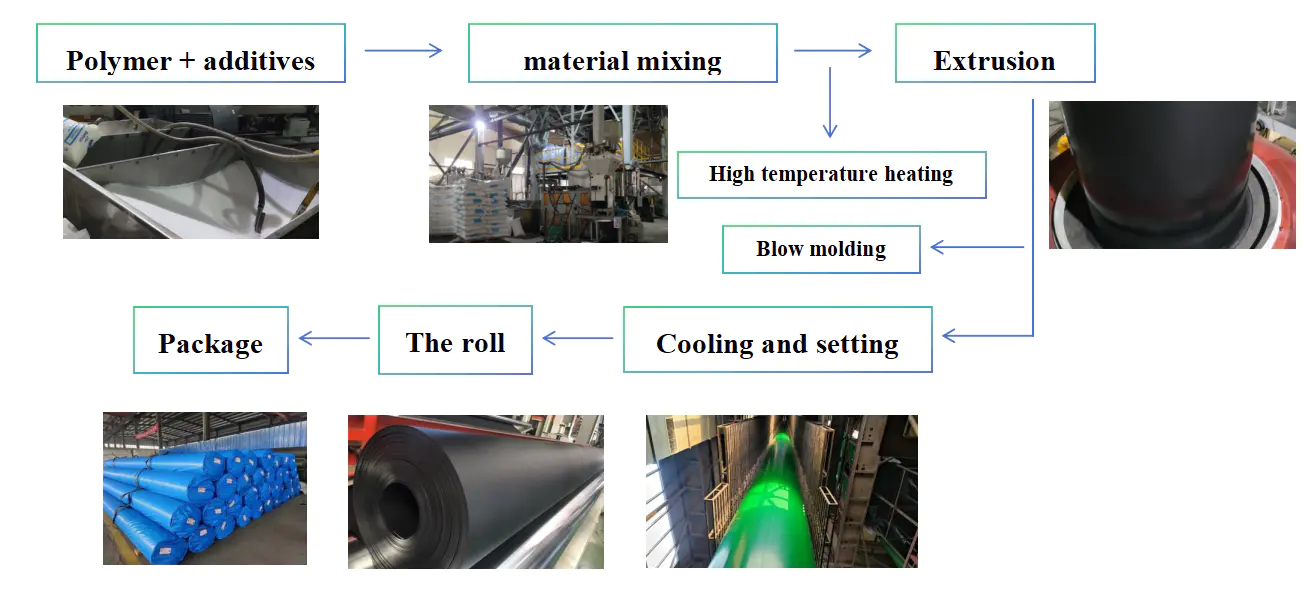

1.4 Production process: The production process of geomembrane will also affect the service life of HDPE liner. We ensure that it can produce stable products at any time through regular updates, maintenance and upkeep of geomembrane equipment. Inferior equipment is prone to uneven mixing of raw materials, affecting the stability of product thickness and quality.

The impact of construction quality on HDPE Liner

Construction quality is also an important factor affecting the service life of geomembranes. Please check out another article we published: 10 important notes for geomembranes installation or video

2.1 Flatness of installation: The geomembrane should be kept flat during installation to avoid wrinkles or bubbles. Uneven installation may cause stress concentration, cause local damage, and reduce the use time of the geomembrane.

2.2 Quality of welding seams: Weak welding may cause leakage and affect the anti-leakage performance of the HDPE LINER system.

2.3 Damage and puncture: During the construction process, there should be reasonable arrangements for the temporary storage of geomembranes. Although geomembranes have good puncture resistance, attention should still be paid to the protection of geomembranes during transportation, storage or installation.

2.4 Construction supervision: During the construction process of the geomembrane, construction personnel should always pay attention to whether the geomembrane is damaged and whether the welding seams meet the requirements. It is recommended to test the integrity of the geomembrane through a seal detection instrument.

2.5 Smoothness of the ground: Before laying the geomembrane, ensure that the ground is flat and free of sharp objects. Uneven ground will cause instability or damage to the geomembrane, which will reduce the service life of the geomembrane.

HDPE Liner Usage Environment

3.1 Ultraviolet rays: If the geomembrane is exposed to the sun for a long time, it will be exposed to ultraviolet radiation. Ultraviolet rays will accelerate the aging process of the geomembrane, reduce the performance of the geomembrane, and shorten its service life.

3.2 Temperature changes: Temperature fluctuations will also affect the service life of the geomembrane. High temperatures may cause the material to soften, deform and accelerate aging. Too low a temperature may reduce the toughness of the geomembrane and cause rupture.

3.3 Chemical substances: During the use of the geomembrane, it will come into contact with various chemical substances, such as acid and alkali solutions and corrosive chemicals. These chemical substances will corrode the material, resulting in reduced performance and reduced service life.

3.4 Biological erosion: In some specific environments, geomembranes may be eroded by organisms, such as algae, fungi, bacteria, etc. Biological growth on the surface of materials can lead to bioerosion, reducing or destroying integrity and affecting service life.

Summarize

To sum up, the quality of the geomembrane itself plays a decisive role in the service life, but at the same time, the geomembrane is also affected by other external forces. But don’t worry, the geomembranes we manufacture have been tested in the laboratory and are usually Before manufacturing a geomembrane, you need to understand its use environment and other factors in advance, and use different raw material ratios to achieve its required indicators. If you need high-quality HDPE Liner, please refer to the above opinions to avoid unnecessary losses.

Or please contact us, we are always here.

No Comments